Kite Pharma

PORTFOLIO

- Midway through the concept design phase for Kite’s new ground-up cell therapy manufacturing facility, the internal design and construction team faced a challenge. The design team they had hired was behind. They reached out to our team to review the MEP drawings. We found several code violations on the power drawings that would have further delayed the building occupancy date and would have been expensive to remove and reinstall if the systems had already been installed.

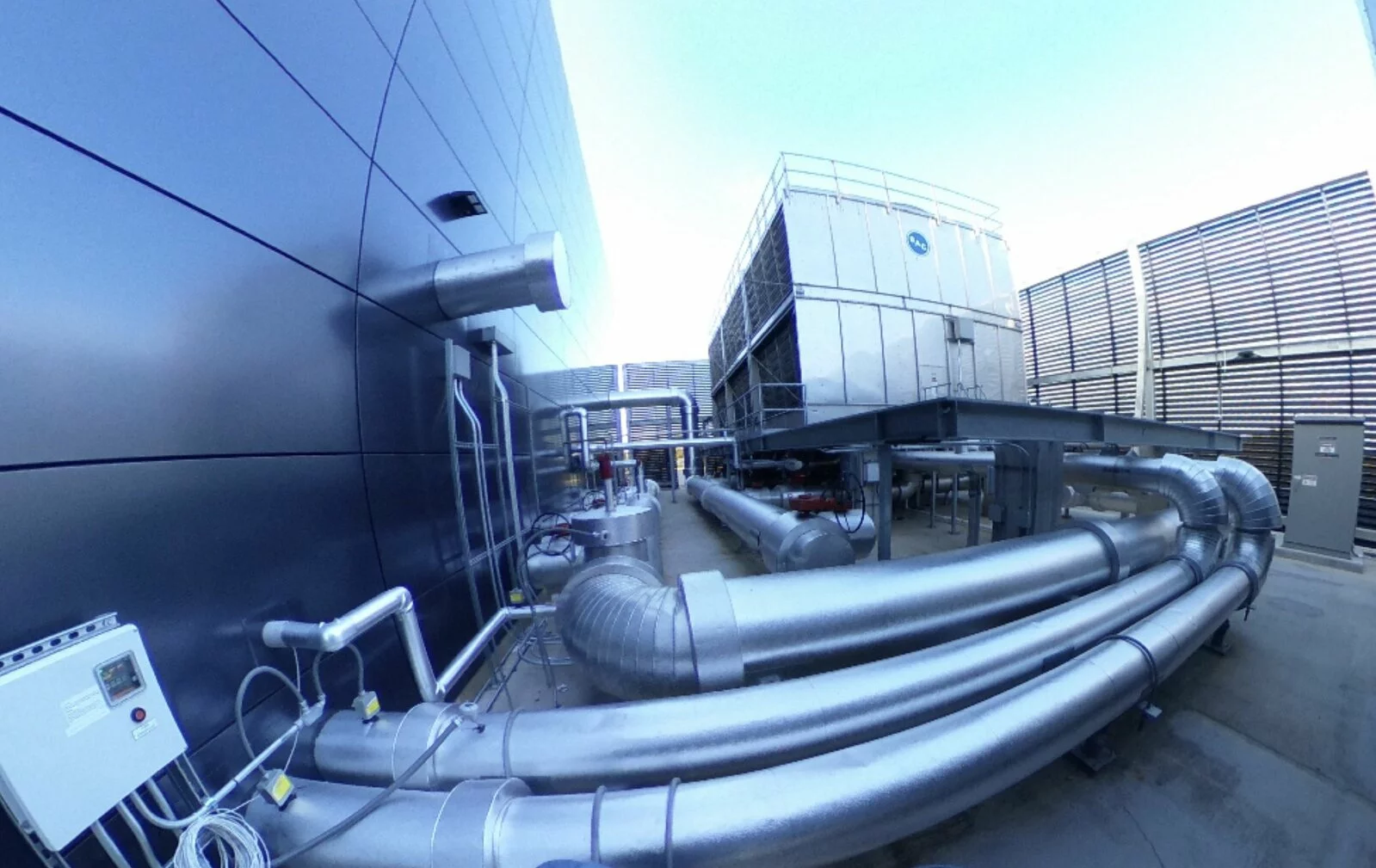

- The revised value engineering layout of the central utility plant limited the expansion of the power and cooling plant. The campus master plan included doubling the site’s R&D and manufacturing capacity, so we proposed options for future plant expansion.

- Energy and cost savings. Our team worked with Kite and Frederick County Officials to reduce the overall connection costs for the building’s sanitary and city water services. Our work resulted in a net savings of $1,200,000.

- We analyzed the amount of expected water consumption to reduce the connection fee by one-third. This enabled Kite to allocate capital to a new water softening system and expedite future designs.

- We advise. As subject matter engineering experts, we work with Kite to advise them on any significant issues that must be addressed before construction.