Our Industry

Save Time & Money on a Project

January 12, 2023

Last year, our team scanned 1.5 million square feet over 87 projects. That is because clients familiar with this technology know how much time and money reality capture scanning can save on a job. Here’s how.

HIDDEN COSTS

First, it is important to understand that hidden costs can quickly add up on a project. Here is an example of what we mean:

A team returns to the office after the initial walk-through of a project site. They have organized notes, photos, and measurements in the project folder. But it’s a project that is not starting for a while, so they use naming conventions and numbering that makes sense at the time. But when the project kicks off, and they look at their notes, all they make out is an electrical panel. They’re missing information. If they can’t get it from someone else, they’ll need to go back on-site. By the time they get what they need and get back to the office, it’s a minimum of three hours later. How much is that time worth? And how much does it cut into the bottom line?

While this is a simple example, avoiding re-work like this adds up. In fact, $250,000 of every $5 million spent on a construction project goes into rework costs.

A VIRTUAL WALK-THROUGH

That is where a virtual walk-through comes in. With a virtual walk-through of the site, all the information can be documented and tagged while the engineers and consultants are doing an initial site visit.

Weeks later, when a project begins, a photo tagged into the walk-throughs allows a team go back to that space. They can continue to work, without the interruption in our earlier example, increasing productivity.

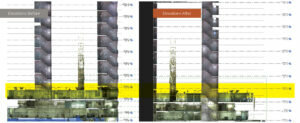

Further, walk-throughs allow us to create a point cloud to verify existing conditions that can be attached to models. This gives us the ability to see locations of beams, conduits, diffusers, and elevations. In the before and after photos below, the elevations are off. With a scan, this was verified and adjusted quickly to be more accurate. To do this manually would require bringing a tape measure to site, using it to measure the floor to ceiling heights, and then calculating out the slab thickness between floors. None of this is necessary with a point cloud because we can visualize and align the model efficiently and accurately. Even more time saved!

Reality capture can be an upfront cost, but long-term by saving time and rework, reality capture is worth the investment. Contact me at jbrooks@wbengineering.com.